Researchers have developed ways of making improved, cheaper transparent silica aerogel composites that could revolutionise windows

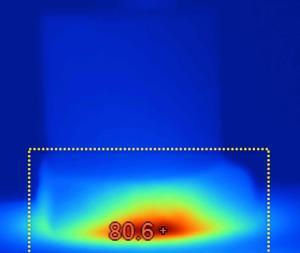

Researchers in the US have developed new methods for manufacturing transparent silica aerogel composites that are significantly cheaper and stronger than current materials. The technology could provide single-pane windows with both thermal and sound insulation.

The collaborative effort between scientists at Virginia Commonwealth University (VCU), the Missouri University of Science and Technology, and the Fraunhofer Center for Sustainable Energy Systems in Boston recently received $800,000 (£562,200) to develop new window materials under a grant from the US Department of Energy’s Advanced Research Projects Agency.

Although aerogels are lightweight and provide excellent sound and thermal insulation, their high manufacturing costs and poor mechanical properties have meant that they have only been used in niche applications, such as for insulation in NASA’s Mars rovers.

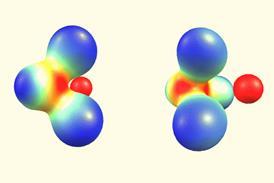

Crosslinking the aggregate of silica nanoparticles with acrylate polymer significantly improves the strength of the aerogel material, but at the expense of its insulation properties. More critically for commercial application, the current multi-step process involves supercritical drying.

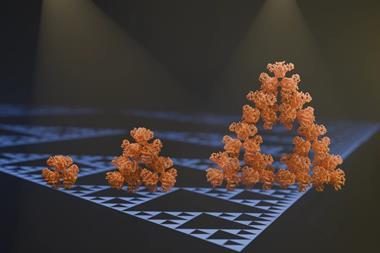

‘The manufacturing costs are prohibitive for anything other than the most expensive applications,’ says Massimo Bertino, a professor of experimental nanoscience at VCU. Bertino’s solution is to use an ethanol-water azeotrope containing monomer as the gelation solvent as the silica nanoparticles are formed, and then to use lithography to initiate photopolymerisation and crosslinking of the nanoparticles only at selected locations in the aerogel material.

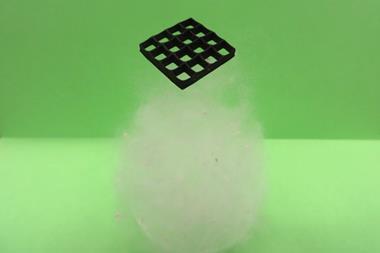

‘The reinforced material can be glued, or even drilled and tapped, leaving the bulk of the structure lightweight and highly insulating,’ says Bertino. ‘The one-pot synthesis is significantly faster, and the solvent can be removed using freeze drying in a vacuum chamber – which is much more affordable than a large scale autoclave.’

‘Replacement of single-pane windows with efficient, modern windows is not always feasible,’ says Karma Sawyer, a commercialisation manager at the US Department of Energy’s Building Technologies Office. ‘If the team is successful, this technology could provide more affordable, highly insulating silica aerogel materials for window retrofits.’

No comments yet