Abstract

Carinata meal (CM), the biomass residue obtained after oil is extracted from the seeds of the inedible crop Brassica carinata, needs to be valorized to enhance the feasibility of sustainable aviation fuel production from carinata oil. Various chemical pretreatment methods (acid, alkali, lime, and peroxide) were tested on CM, which was then enzymatically hydrolyzed to produce sugar-rich hydrolysate that is readily fermentable by microorganisms. A maximum glucose concentration of 38 g/L was obtained after pretreatment with concentrated phosphoric acid. Moreover, the CM residue remaining after enzymatic hydrolysis was converted via hydrothermal carbonization (HTC) to hydrochar, whose properties, such as combustion profile and surface functional groups, depended on the HTC temperature. The hydrochar had a carbon content (55.8–60.5%) and an ash content (6.6–14.8%) appropriate for use as solid fuel, whose heating value (22.7–25.1 MJ/kg) is close to that of bituminous coal. Both sugar hydrolysate and hydrochar represent renewable coproducts that can add value to the commercial development of fuels and chemicals from Brassica carinata.

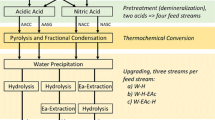

Graphical abstract

Similar content being viewed by others

Data availability

Not applicable.

Code availability

Not applicable.

Change history

25 July 2022

A Correction to this paper has been published: https://doi.org/10.1007/s13399-022-03092-x

References

Ammar EM, Martin J, Philippidis GP (2021) Biochemical conversion of Brassica carinata biomass to organic acids. GCB Bioenergy 13(4):618–626. https://doi.org/10.1111/gcbb.12812

Kumar S, Seepaul R, Mulvaney MJ, Colvin B, George S, Marois JJ, Bennett R, Leon R, Wright DL, Small IM (2020) Brassica carinata genotypes demonstrate potential as a winter biofuel crop in South East United States. Ind Crops Prod 150:112353. https://doi.org/10.1016/j.indcrop.2020.112353

George S, Seepaul R, Geller D, Dwivedi P, DiLorenzo N, Altman R, Coppola E, Miller SA, Bennett R, Johnston G, Streit L, Csonka S, Field J, Marois J, Wright D, Small I, Philippidis GP (2021) A regional inter-disciplinary partnership focusing on the development of a carinata-centered bioeconomy. GCB Bioenergy 13(7):1018–1029. https://doi.org/10.1111/gcbb.12828

Karmee SK (2016) Liquid biofuels from food waste: Current trends, prospect and limitation. Renew Sust Energ Rev 53:945–953. https://doi.org/10.1016/j.rser.2015.09.041

Lee SY, Sankaran R, Chew KW, Tan CH, Krishnamoorthy R, Chu DT, Show PL (2019) Waste to bioenergy: a review on the recent conversion technologies. BMC Energy 1(1):4. https://doi.org/10.1186/s42500-019-0004-7

Jönsson LJ, Martín C (2016) Pretreatment of lignocellulose: Formation of inhibitory by-products and strategies for minimizing their effects. Bioresour Technol 199:103–112. https://doi.org/10.1016/j.biortech.2015.10.009

Sharma HK, Xu C, Qin W (2019) Biological Pretreatment of Lignocellulosic Biomass for Biofuels and Bioproducts: An Overview. Waste Biomass Valor 10(2):235–251. https://doi.org/10.1007/s12649-017-0059-y

Singh S, Cheng G, Sathitsuksanoh N, Wu D, Varanasi P, George A, Balan V, Gao X, Kumar R, Dale BE, Wyman CE, Simmons BA (2015) Comparison of Different Biomass Pretreatment Techniques and Their Impact on Chemistry and Structure. Front. Energy Res 2(62). https://doi.org/10.3389/fenrg.2014.00062

Schulmeister TM, Ruiz-Moreno M, Silva GM, Garcia-Ascolani M, Ciriaco FM, Henry DD, Lamb GC, Dubeux JCB Jr, Dilorenzo N (2019) Evaluation of Brassica carinata meal as a protein supplement for growing beef heifers. J Anim Sci 97(10):4334–4340. https://doi.org/10.1093/jas/skz280

Lee J, Lee K, Sohn D, Kim YM, Park KY (2018) Hydrothermal carbonization of lipid extracted algae for hydrochar production and feasibility of using hydrochar as a solid fuel. Energy 153:913–920. https://doi.org/10.1016/j.energy.2018.04.112

Puccini M, Stefanelli E, Hiltz M, Seggiani M, Vitolo S (2017) Activated Carbon from Hydrochar Produced by Hydrothermal Carbonization of Wastes. Chem Eng Trans 57:169–174. https://doi.org/10.3303/CET1757029

Tsarpali M, Arora N, Kuhn JN, Philippidis GP (2021) Lipid-extracted algae as a source of biomaterials for algae biorefineries. Algal Res 57:102354. https://doi.org/10.1016/j.algal.2021.102354

Aydıncak K, Yumak T, Sınağ A, Esen B (2012) Synthesis and characterization of carbonaceous materials from saccharides (Glucose and Lactose) and two waste biomasses by hydrothermal carbonization. Ind Eng Chem Res 51(26):9145–9152. https://doi.org/10.1021/ie301236h

Basso D, Patuzzi F, Castello D, Baratieri M, Rada EC, Weiss-Hortala E, Fiori L (2016) Agro-industrial waste to solid biofuel through hydrothermal carbonization. Waste Manage 47:114–121. https://doi.org/10.1016/j.wasman.2015.05.013

Jena U, Vaidyanathan N, Chinnasamy S, Das KC (2011) Evaluation of microalgae cultivation using recovered aqueous co-product from thermochemical liquefaction of algal biomass. Bioresour Technol 102(3):3380–3387. https://doi.org/10.1016/j.biortech.2010.09.111

Kang S, Li X, Fan J, Chang J (2012) Characterization of hydrochars produced by hydrothermal carbonization of lignin, cellulose, d-Xylose, and wood meal. Ind Eng Chem Res 51(26):9023–9031. https://doi.org/10.1021/ie300565d

Kobayashi H, Fukuoka A (2013) Synthesis and utilisation of sugar compounds derived from lignocellulosic biomass. Green Chem 15(7):1740–1763. https://doi.org/10.1039/C3GC00060E

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D, Crocker D (2008) Determination of structural carbohydrates and lignin in biomass. Laboratory Analytical Procedure (LAP). National Renewable Energy Laboratory

Lo E, Brabo-Catala L, Dogaris I, Ammar EM, Philippidis GP (2020) Biochemical conversion of sweet sorghum bagasse to succinic acid. J Biosci Bioeng 129(1):104–109. https://doi.org/10.1016/j.jbiosc.2019.07.003

Karagöz P, Rocha IV, Özkan M, Angelidaki I (2012) Alkaline peroxide pretreatment of rapeseed straw for enhancing bioethanol production by Same Vessel Saccharification and Co-Fermentation. Bioresour Technol 104:349–357. https://doi.org/10.1016/j.biortech.2011.10.075

Panagiotopoulos IA, Bakker RR, de Vrije T, Koukios EG, Claassen PAM (2010) Pretreatment of sweet sorghum bagasse for hydrogen production by Caldicellulosiruptor saccharolyticus. Int J Hydrog Energy 35(15):7738–7747. https://doi.org/10.1016/j.ijhydene.2010.05.075

Xu J, Cheng JJ, Sharma-Shivappa RR, Burns JC (2010) Lime pretreatment of switchgrass at mild temperatures for ethanol production. Bioresour Technol 101(8):2900–2903. https://doi.org/10.1016/j.biortech.2009.12.015

Cao W, Sun C, Qiu J, Li X, Liu R, Zhang L (2016) Pretreatment of sweet sorghum bagasse by alkaline hydrogen peroxide for enhancing ethanol production. Korean J Chem Eng 33(3):873–879. https://doi.org/10.1007/s11814-015-0217-5

Adney B, Baker J (2008) Measurement of cellulase activities. Laboratory Analytical Procedure (LAP). National Renewable Energy Laboratory

Chen H, Han Y, Xu J (2008) Simultaneous saccharification and fermentation of steam exploded wheat straw pretreated with alkaline peroxide. Process Biochem 43(12):1462–1466. https://doi.org/10.1016/j.procbio.2008.07.003

Broch A, Jena U, Hoekman S, Langford J (2012) Analysis of solid and aqueous phase products from hydrothermal carbonization of whole and lipid-extracted algae. Energies 7:62–79. https://doi.org/10.3390/en7010062

Mathanker A, Pudasainee D, Kumar A, Gupta R (2020) Hydrothermal liquefaction of lignocellulosic biomass feedstock to produce biofuels: Parametric study and products characterization. Fuel 271:117534. https://doi.org/10.1016/j.fuel.2020.117534

Dar R, Dar E, Kaur A, Phutela U (2017) Sweet sorghum-a promising alternative feedstock for biofuel production. Renew Sust Energ Rev 82(3):4070–4090. https://doi.org/10.1016/j.rser.2017.10.066

Nakrani MN, Wineland RH, Anjum F (2021) Physiology, Glucose Metabolism. StatPearls Publishing, Treasure Island (FL)

Chundawat SPS, Balan V, Sousa LDc, Dale BE (2010) Thermochemical pretreatment of lignocellulosic biomass. In: Waldron K (ed) Bioalcohol production. Woodhead Publishing, pp 24–72

Yoo CG, Meng X, Pu Y, Ragauskas AJ (2020) The critical role of lignin in lignocellulosic biomass conversion and recent pretreatment strategies: A comprehensive review. Bioresour Technol 301:122784. https://doi.org/10.1016/j.biortech.2020.122784

Nizamuddin S, Baloch HA, Griffin GJ, Mubarak NM, Bhutto AW, Abro R, Mazari SA, Ali BS (2017) An overview of effect of process parameters on hydrothermal carbonization of biomass. Renew Sust Energ Rev 73:1289–1299. https://doi.org/10.1016/j.rser.2016.12.122

Mäkelä M, Benavente V, Fullana A (2015) Hydrothermal carbonization of lignocellulosic biomass: Effect of process conditions on hydrochar properties. Appl Energy 155:576–584. https://doi.org/10.1016/j.apenergy.2015.06.022

Chen X, Ma X, Peng X, Lin Y, Yao Z (2018) Conversion of sweet potato waste to solid fuel via hydrothermal carbonization. Bioresour Technol 249:900–907. https://doi.org/10.1016/j.biortech.2017.10.096

Akarsu K, Duman G, Yilmazer A, Keskin T, Azbar N, Yanik J (2019) Sustainable valorization of food wastes into solid fuel by hydrothermal carbonization. Bioresour Technol 292:121959. https://doi.org/10.1016/j.biortech.2019.121959

Tan Y, Croiset E, Douglas MA, Thambimuthu KV (2006) Combustion characteristics of coal in a mixture of oxygen and recycled flue gas. Fuel 85(4):507–512. https://doi.org/10.1016/j.fuel.2005.08.010

Engineering ToolBox (2010) Standard Grade Coal - Heat Values. Available at https://www.engineeringtoolbox.com/coal-heating-values-d_1675.html. Accessed 17 Nov 2021

Taskin E, de Castro BC, Allegretta I, Terzano R, Rosa AH, Loffredo E (2019) Multianalytical characterization of biochar and hydrochar produced from waste biomasses for environmental and agricultural applications. Chemosphere 233:422–430. https://doi.org/10.1016/j.chemosphere.2019.05.204

Zhang Y, Jiang Q, Xie W, Wang Y, Kang J (2019) Effects of temperature, time and acidity of hydrothermal carbonization on the hydrochar properties and nitrogen recovery from corn stover. Biomass Bioenergy 122:175–182. https://doi.org/10.1016/j.biombioe.2019.01.035

Ferrentino R, Ceccato R, Marchetti V, Andreottola G, Fiori L (2020) Sewage Sludge Hydrochar: An Option for Removal of Methylene Blue from Wastewater. Appl Sci 10(10):3445. https://doi.org/10.3390/app10103445

Toufiq M, Nover J, Herklotz B, Coronella C (2016) Hydrothermal carbonization of glucose in saline solution: sequestration of nutrients on carbonaceous materials. AIMS Energy 4:173–189. https://doi.org/10.3934/energy.2016.1.173

Liu F, Yu R, Guo M (2017) Hydrothermal carbonization of forestry residues: influence of reaction temperature on holocellulose-derived hydrochar properties. J Mater Sci 52(3):1736–1746. https://doi.org/10.1007/s10853-016-0465-8

Jaiswal KK, Kumar V, Verma R, Verma M, Kumar A, Vlaskin MS, Nanda M, Kim H (2021) Graphitic bio-char and bio-oil synthesis via hydrothermal carbonization-co-liquefaction of microalgae biomass (oiled/de-oiled) and multiple heavy metals remediations. J Hazard Mater 409:124987. https://doi.org/10.1016/j.jhazmat.2020.124987

Jain A, Balasubramanian R, Srinivasan MP (2016) Hydrothermal conversion of biomass waste to activated carbon with high porosity: A review. Chem Eng J 283:789–805. https://doi.org/10.1016/j.cej.2015.08.014

Guo S, Dong X, Liu K, Yu H, Zhu C (2015) Chemical, Energetic, and Structural Characteristics of Hydrothermal Carbonization Solid Products for Lawn Grass. BioResources 10(3):4613–4625. https://doi.org/10.15376/biores.10.3.4613-4625

Röhrdanz M, Rebling T, Ohlert J, Jasper J, Greve T, Buchwald R, von Frieling P, Wark M (2016) Hydrothermal carbonization of biomass from landscape management – Influence of process parameters on soil properties of hydrochars. J Environ Manage 173:72–78. https://doi.org/10.1016/j.jenvman.2016.03.006

Wang T, Zhai Y, Zhu Y, Li C, Zeng G (2018) A review of the hydrothermal carbonization of biomass waste for hydrochar formation: Process conditions, fundamentals, and physicochemical properties. Renew Sust Energ Rev 90:223–247. https://doi.org/10.1016/j.rser.2018.03.071

Khoo CG, Lam MK, Mohamed AR, Lee KT (2020) Hydrochar production from high-ash low-lipid microalgal biomass via hydrothermal carbonization: Effects of operational parameters and products characterization. Environ Res 188:109828. https://doi.org/10.1016/j.envres.2020.109828

Tsarpali M, Arora N, Kuhn JN, Philippidis GP (2021) Beneficial use of the aqueous phase generated during hydrothermal carbonization of algae as nutrient source for algae cultivation. Algal Res 60:102485. https://doi.org/10.1016/j.algal.2021.102485

Acknowledgements

The authors wish to thank M. Yung of NREL for technical assistance.

Funding

This research was funded by USDA-NIFA Bioenergy-Coordinated Agricultural Projects Grant # 2016–11231 to GPP.

Author information

Authors and Affiliations

Contributions

Magdalini Tsarpali, Jessica Martin, John N. Kuhn, and George P. Philippidis were involved in Conceptualization; Magdalini Tsarpali and Jessica Martin had contributed to investigation, methodology, data curation, software, formal analysis, visualization, and writing the original draft; John N. Kuhn and George P. Philippidis were responsible for supervision, project administration, resources, funding acquisition, and writing, reviewing, and editing.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

All authors agree to participate in the study.

Consent for publication

All authors agree to submit the manuscript for publication to the Biomass Conversion and Biorefinery Journal.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Value-added coproducts are essential to Brassica carinata commercialization

• Biomass of carinata meal (CM) was chemically pretreated using various methods

• Pretreated CM was enzymatically hydrolyzed to glucose at high concentrations

• Residual CM after enzymatic hydrolysis was converted to hydrochar

• Hydrochar properties varied with hydrothermal carbonization temperature

The original online version of this article was revised: Figure 3 has been replaced with the correct panel (a) of the SEM image.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tsarpali, M., Martin, J., Kuhn, J. et al. Valorization of Brassica carinata biomass through conversion to hydrolysate and hydrochar. Biomass Conv. Bioref. (2022). https://doi.org/10.1007/s13399-022-02578-y

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-022-02578-y